行业知识

Home>Industry knowledge>Content

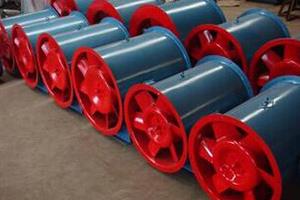

When the air between the blades of the centrifugal fan rotates, the kinetic energy is discharged from the periphery of the impeller by the action of centrifugal force, and is guided by the volute casing to move to the outlet of the fan, thereby forming a negative pressure at the center of the impeller. Make the external air flow continuously into the compensation, so that the fan can discharge the gas. Let's take a look at the editor belowHigh-pressure blower manufacturersAn introduction to the working principle of a centrifugal fan, I hope you can solve your troubles.

The centrifugal fan is mainly composed of an impeller and a casing. The impeller of a small fan is directly mounted on the motor, and the large fan is connected with the motor through a coupling or a pulley.High-pressure blower manufacturersThe anti-corrosion fan is generally single-sided air intake, using a single-stage impeller; for large flow, it can be double-sided air intake, using two back-to-back impellers, which is also called a double-suction centrifugal fan.

The impeller is the main component of the anti-corrosion fan. Its geometry, standard, number of blades and manufacturing accuracy have a great influence on the function. The impeller can be adjusted by static balance or dynamic balance to ensure the smooth rotation of the fan. According to the different direction of the blade outlet, the impeller is divided into three types: forward, radial and backward.

The pressure generated by the forward impeller is the largest. When the flow rate and the number of revolutions are constant, the required impeller diameter is the smallest, but the power is generally low; the backward impeller is opposite, the pressure generated is the smallest, the required impeller diameter is the largest, and the power is generally higher ; The radial impeller is between the two. The blade profile is simplest with straight blades, and airfoil blades are the most complicated.

In order to make the blade surface have a suitable speed spread, generally choose curved blades, such as equal thickness arc blades. The impeller generally has a cover disc to increase the strength of the impeller and reduce the gas leakage between the blade and the casing. The connection between the blade and the cover plate is welded or riveted. The weight of the welded impeller is lighter and the runner is smooth. The impellers of low and medium pressure small centrifugal fans are also casted in aluminum alloy.

The above is what the editor brings to you today. If you are interested in our products and want to know more about it, you can follow our official website and we will update the news regularly. You can also call our hotline, we have the most Professional staff will solve the problem for you, and finally hope that you can cooperate with us to achieve our goal of mutual creation and win-win!